A Modern Legacy

Four generations and a 106 years after the founding of a Maltese winery in 1907 by Eduardo Delicata, Emmanuel Delicata Winemaker Ltd is still the privately owned, family run business it always was, but with a few noticeable changes.

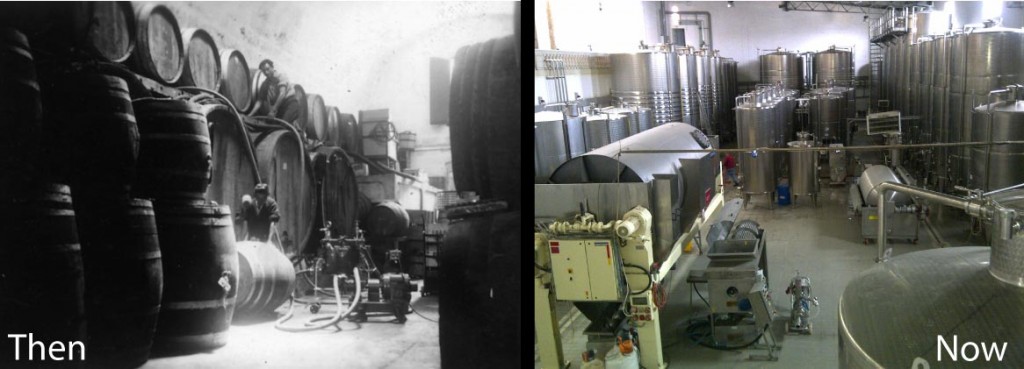

Over a century later, this once rudimentary wine making practice that was based on wooden barrels and horse drawn carts has now evolved into a thriving modern winery more akin to a cathedral of stainless steel. But the fundamentals are still the same 106 years on. Just as Eduardo and his son Emmanuel did back ‘in the day’, their descendents do today; and that’s to simply concentrate their efforts exclusively on the production of making wine.

However, back at the turn of the last century, the material of choice for fermenting wines all over the world was a combination of raw cement vats and old wooden barrels. Even right up until the 1960’s wine vats had only advanced as far as epoxy or glass lined tanks and fiberglass vats – many of which, in certain wineries are still in use today. But the winemaking insurrection came about in the early 1960’s, driven by the famous French winemaking legend Emile Peynaud, who advocated the use of stainless steel tanks in the winemaking process after observing their success in the dairy industry. One of the Chateaux listening to Peynaud was the first growth Bordeaux Chateau Haut Brion and in 1961, this legendary Bordeaux producer was one of the first wineries in the world to install stainless steel tanks and in the process revolutionise winemaking; and it wasn’t long after that, that many other wineries followed suit.

The main reason for the success of stainless steel tanks was that, together with refrigeration, the temperature control of the must (grape juice), was for the very first time, in the hands of the winemaker, because along with alcohol and carbon dioxide, heat is a byproduct of the fermentation process. Fermentation will only take place between certain temperatures and the fermentation temperature has an enormous impact on the style of the finished wine. Warmer temperatures agitate the must and impart stronger flavors and aromas. While this is the goal for most red wines, it would produce a brash, unbalanced white wine. Cooler temperatures will retain the delicate varietal flavors and aromas that most white wines are valued for.

Stainless steel containers therefore are very efficient at controlling the fermentation temperature. They have a chamber surrounding the tank that holds coolant and there are controls on the tank that allow the winemaker to maintain the temperature he wants to produce the style of wine he requires. They also make it easier to prevent oxidation, monitor the fermentation and attach other winemaking tools. Most have closed tops in order to minimize the amount of air contact during the fermentation process.

Stainless steel is completely neutral in the winemaking process and unlike wood and poorly maintained cement tanks do not impart any characteristics into the wine. This makes them useful not only for fermentation, but also as holding tanks. Wine is constantly being racked from tank to tank, and they are very useful during this process. They can also be used for cold stabilization which helps give the wine more clarity and they have a longer useful life than other fermentation containers and can be more efficient, environmentally friendly and economical over the long term.

Delicata now has stainless steel tanks in abundance ranging in size from 10 hectolitre to 300 hectolitre and they include 2 Ganimede fermenters – the very latest technologically advanced stainless steel tanks that allow the scientific management of gases. In the last 18 months alone, 32 white wine tanks and red wine fermenters have been installed at the winery, as part of the winemakers drive to continually upgrade their equipment with the very latest wine technology available; and to thereby determinedly improve the quality of their wines. These latest tanks will enable Delicata to ferment even smaller individual parcels of very high quality grapes – the first of which will start rolling into the winery in about 18 weeks time.